SERVICES

Looking for electronics product design?

Xentech Solutions Limited, established in 2007, has been developing electronics and embedded software for a wide variety of products over many years.

Specialists in the development of networking, communications and control devices, the design team are experienced in a wide range of technologies such as Ethernet, WiFi, Bluetooth and other licence free radios and are used to working with embedded microprocessors from ARM and NXP to name but two. For more sophisticated designs, we can develop a custom FPGA using VHDL or Verilog to suit your specific requirements.

Our embedded software development can be anything from bare metal bring-up on new chips using C, to a fully-fledged embedded Linux operating system and APIs, depending on what the project needs.

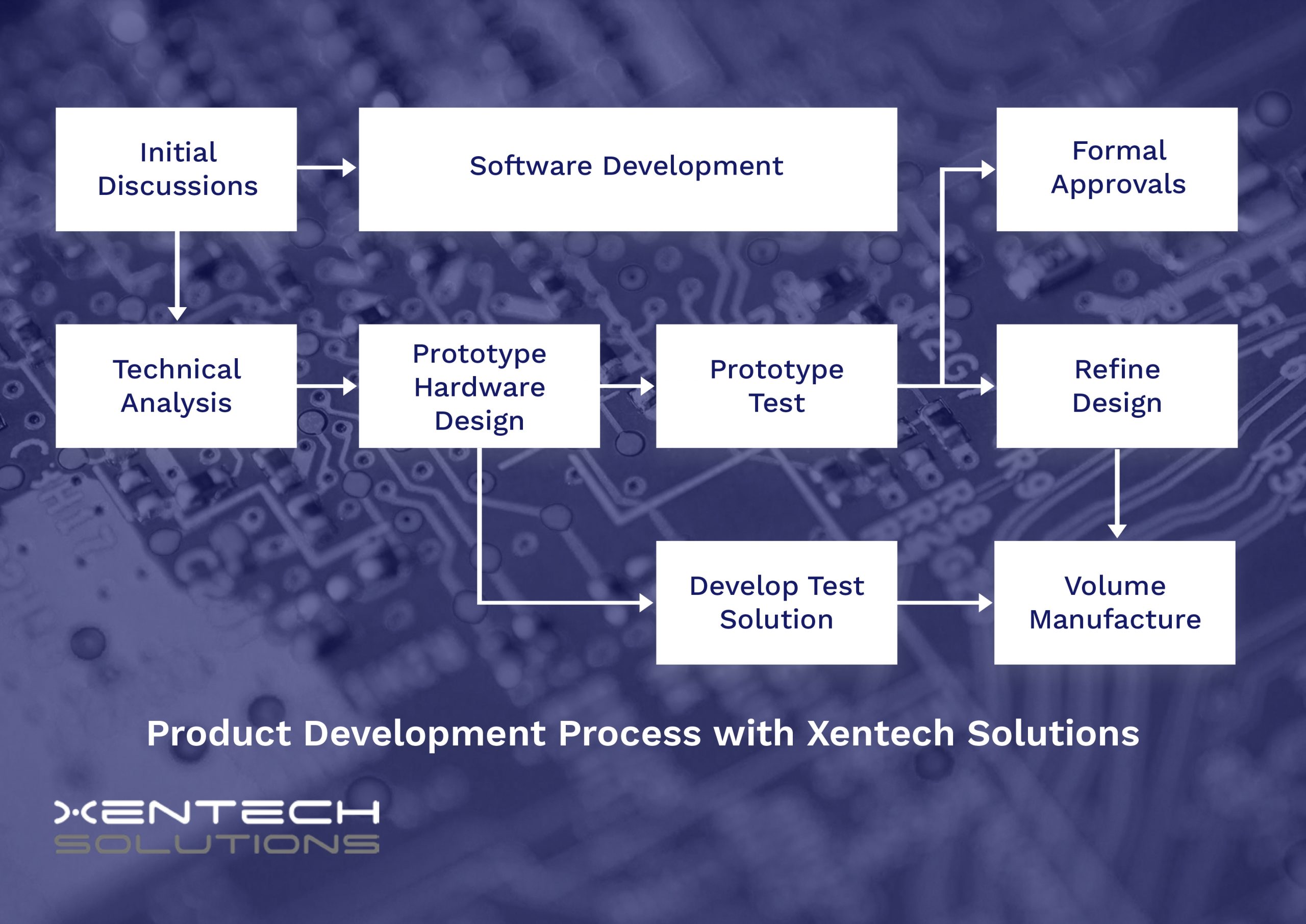

Equally at home with developing a product design from conception to completion or working with your existing team to add specific skills or to overcome a resource shortage, Xentech Solutions can help you deliver a fully tested design using a robust and cost efficient development process.

But design alone is not all. Once the hardware design has been completed, there is a need to get it manufactured and Xentech Solutions has relationships with UK based contract electronic manufacturers to produce prototypes for evaluation and to make the introduction into volume manufacturing as seamless as possible. Whether you are looking for a small number of prototypes or a production run of thousands, Xentech Solutions can select a manufacturer to meet your requirements and ensure you receive quality, tested, product.

Talk to us today about how we can help you turn your product idea into reality.

How does it work?

With Xentech Solutions, it is easy to engage for a first level discussion about how we can help you achieve your project goals. Just use the contact page or give us a call during UK office hours. You will talk directly to an experienced and friendly engineer who can explain our process in detail and answer any questions about what we do best to help you succeed.

A typical project engagement will start with a couple of telephone conference calls to help us understand what you are trying to do and how we can help. The first call is usually a chance for both parties to set the scene about what is required and establish how well our skills and experience match your needs anything from a brand new product innovation to help with managing obsolescence in an existing design. The second call is after we have thought about the requirements a bit and gives us a chance to ask all the questions we forgot to ask the first time!

Once our team has a good understanding of what is required, a dedicated project manager will develop a project proposal for you to review, including costed plan of work, so that you know exactly what we can do to get your product idea to fruition.

What else?

Designing an electronic product is a complex process to get right, it is not just the design of the functionality itself to think about, but also how the design gets manufactured and tested to ensure your customers receive only the best quality product. And that is not all; to take a product to market you will need to comply with all the relevant legislation for the country you are selling in to. For example the UK now requires UKCA marking on most electronic products and the CE mark is still a requirement for selling into Europe. Xentech Solutions can help ensure your product complies and is safe by using UKAS accredited test laboratories to independently certify the design.

When introducing a product design into volume manufacture, it is important that the design can be adequately tested as it is built. Working with the chosen manufacturer, Xentech Solutions will develop a manufacturing test solution that is suitable for the volumes being manufactured and easy to use. By developing a custom automated test solution, it is possible to ensure excellent product quality without having to rely on human interaction. If you are seeing product quality issues in your existing process, why not talk to us for advice about what to change?

Sometimes you might need specialist skills for one aspect of a product design. Xentech Solutions engineers have strong experience in solving problems. There is nothing they like more than getting their teeth into a difficult technical issue and finding a pathway to resolution. As well as tracking down the root cause of an issue, Xentech engineers will provide pragmatic advice on how to resolve the problem in a cost effective way. If you have a tricky embedded software problem, or signal integrity issues in your current design, why not let Xentech Solutions take a look for you?

FPGA Design

If you are looking for help with an FPGA design, Xentech Solutions has many years’ experience of working with all the major FPGA vendors such as Xilinx, Altera, Lattice and Achronix. Using Verilog or VHDL we can design a specific function or a complete system on a chip to meet your requirements. With an in-house software team we can also provide software drivers and custom firmware to help integrate functions into a complete system making it easy for you to develop your product.

Component Obsolescence

As designs age component obsolescence can become a real problem, increasing lead times and making product manufacture almost impossible. At Xentech Solutions we work closely with manufacturers and supply chains to review a design for manufacturability. As an independent consultancy, we can also select manufacturers that have the processes best suited to your particular design and volumes. If a PCB re-design is required, Xentech Solutions own engineers can take your existing design and reverse engineer it to understand the functionality. With that knowledge we can update the design to use modern components with a long expected availability. A re-design can be an exact form, fit and function replacement or you can use the opportunity to upgrade functionality or the user interfaces to get a more modern “look and feel”. Talk to us today to find out more.

UKCA Approvals

With the UK having left the EU, it is important to make sure that any product design meets not only the CE approvals requirements, if you want to continue to sell into the European Market, but also the new UKCA approvals requirements. Xentech Solutions can help you navigate this path and will work with accredited test houses to verify that your product design meets the relevant requirements.

And if you are selling worldwide, then there are many further consideration to be considered such as UL and FCC compliance for the USA, PSE and VCCI approvals for Japan or GKRCH and GOST-R for Russia to list but a few.

OTHER SERVICES

Enclosure Design

With a network of partners, Xentech Solutions can do more than just design your electronics and software. What about enclosure design? From 19” rack mounted chassis to 3D printed prototypes, Xentech Solutions can manage your design process to ensure your product looks as good as it performs. Talk to us today to find out more.

User Manuals and Documentation

Often overlooked during the early design process, a professionally produced user manual will enhance your customers’ enjoyment of the product. For most products the user interface itself should be self-explanatory but for more sophisticated designs then comprehensive instructions for use are critical. For complex products, Xentech Solutions works with a small number of specialist companies to provide extensible product documentation to ensure not only good documentation, but also maintainable documentation.